INNOVATION IS WHAT SETS US APART

Advanced technology is the product of ingenuity and experience, which our team has cultivated through the Scout Downhole culture.

Find TheRight Solutions

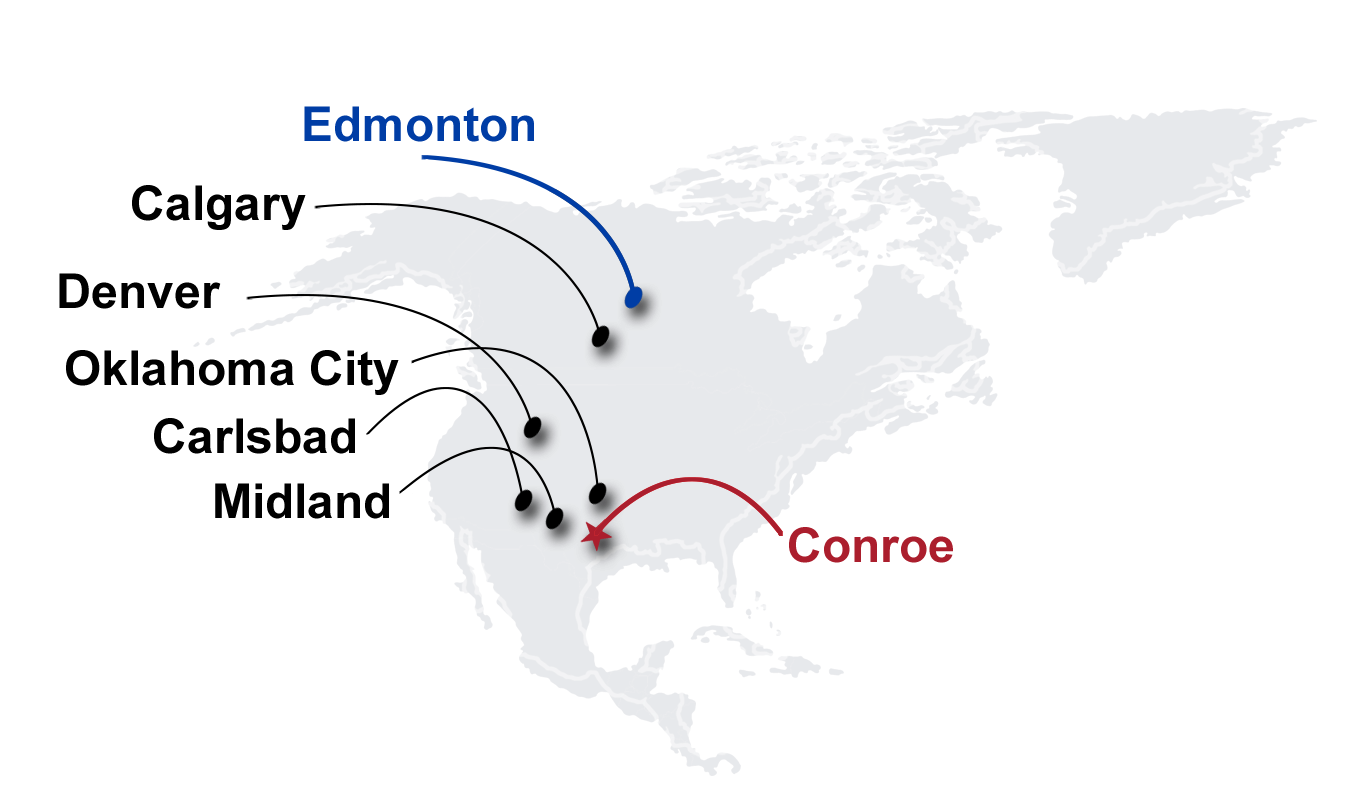

Scout Downhole® is a privately held company founded in 2009 to provide innovative oilfield products, high-quality manufacturing, and customer service excellence. New product development and continuous improvement are at the heart of our business philosophy. While other companies continue with their same equipment offering for many years, Scout Downhole offers cutting-edge downhole drilling rental products and solutions, which continue to evolve with industry needs.

Our Fields of Expertise: